In the construction industry, it’s common practice to begin each day with a job hazard analysis. This typically involves a comprehensive list of potential hazards on the jobsite, accompanied by a generic plan for prevention. While these analyses can be effective, they often risk being treated as mere formalities and not given the serious attention they require. When hazard lists are created based solely on past experiences, they tend to become repetitive, leading to the likelihood that employees will overlook them as background noise.

At FTI, we prioritize Operational Risk Management (ORM) rather than relying on routine hazard lists. Every day, our dedicated team actively engages in the ORM process. While many are familiar with the acronym ORM, the concept of operational risk itself may need to be better understood.

So, what exactly is operational risk? The dictionary defines it as the potential for loss resulting from inadequate or failed internal processes, people, systems or external events. However, this textbook definition only partially captures the real-world significance of operational risk in our daily work. The range of possible hazards and mitigations is endless if one considers every conceivable scenario. Instead of focusing on hypothetical risks, we concentrate on the risks that are most likely to occur and develop actionable plans to mitigate them so that we can ensure that this information remains relevant and top-of-mind for our workers.

When introducing the concept of operational risk to others, I start by asking them to define success for themselves. I often ask, “What does a successful day today look like to you?” Once they answer, I follow up with, “What could prevent you from achieving that success?” These two questions form the foundation of operational risk and set the stage for effective operational risk management.

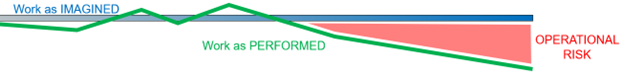

Think of every task we undertake as following a blueprint for success. This plan can be visualized as a straight line—let’s call it work as imagined. This line represents our goals: meeting schedules, adhering to quality standards, sticking to budgets and ensuring safety. A robust plan is specific, measurable, achievable, realistic and time-bound. Once the plan is in place, it’s time to bring it to life.

In practice, executing a plan is rarely straightforward. This is where the concept of work as performed comes into play—a reality that often diverges from our work as imagined. The work as performed line is fluid and subject to various changes. When we exceed expectations or complete tasks ahead of schedule, the work as performed line surpasses the work as imagined line, leading to operational gains. At FTI, programs like our Values Recognition Program (VRP) and workplace innovation awards enable us to acknowledge and celebrate the outstanding contributors who drive our success.

Conversely, when the work as performed line falls short of the work as imagined line, we encounter operational risk. In essence, operational risk represents all the obstacles between us and our objectives. These challenges may include jobsite safety hazards, weather-related delays, budget constraints, unexpected expenses, product delays and unforeseen conditions.

The core of our ORM process lies in the proactive identification and management of risks or obstacles that could hinder our ability to achieve success and ensure safety daily. Through it, we strive to meticulously identify potential risks or barriers that may stand in the way of our daily objectives of maintaining a safe and productive work environment. With a primary goal each day to prevent workplace injuries, it is essential to thoroughly examine the tasks or activities planned and assess which of these could potentially compromise that goal. By identifying these critical points of vulnerability, we can implement strategic adjustments or controls that mitigate the risks, thereby reinforcing our commitment to safety and success. This proactive approach not only helps protect our team but also ensures that our operations continue to run smoothly and efficiently without unforeseen disruptions.

The effectiveness of our daily operations hinges on our ability to accurately identify, assess and manage the risks that could impede our success and safety. Through a focused approach to operational risk management, we move beyond the routine hazard lists to address the real-world challenges that matter most. By aligning our work as performed with our work as imagined, we strive not only to meet but to exceed our expectations, turning potential obstacles into opportunities for growth and operational excellence.

While programs like VRP allow us to recognize individuals who consistently drive us forward, it is equally important to acknowledge the operational risks that may arise when our performance falls short of our expectations. By understanding and mitigating these risks, we can ensure that our objectives remain within reach and that every day ends in success.

Operational risk management is not just a process—it’s a mindset. It requires us to be proactive, vigilant and committed to continuous improvement. By fostering this mindset, we maintain the highest standards of safety and efficiency and continue our goal of building trust in everything we do. Together, we turn challenges into achievements and ensure that our work, both as imagined and as performed, consistently aligns with our vision of success.

Ryan Word is a Safety Manager with Faith Technologies Incorporated (FTI).